Fuel Tanks

A fuel tank is a component that stores vehicle fuel, such as gasoline or diesel oil.

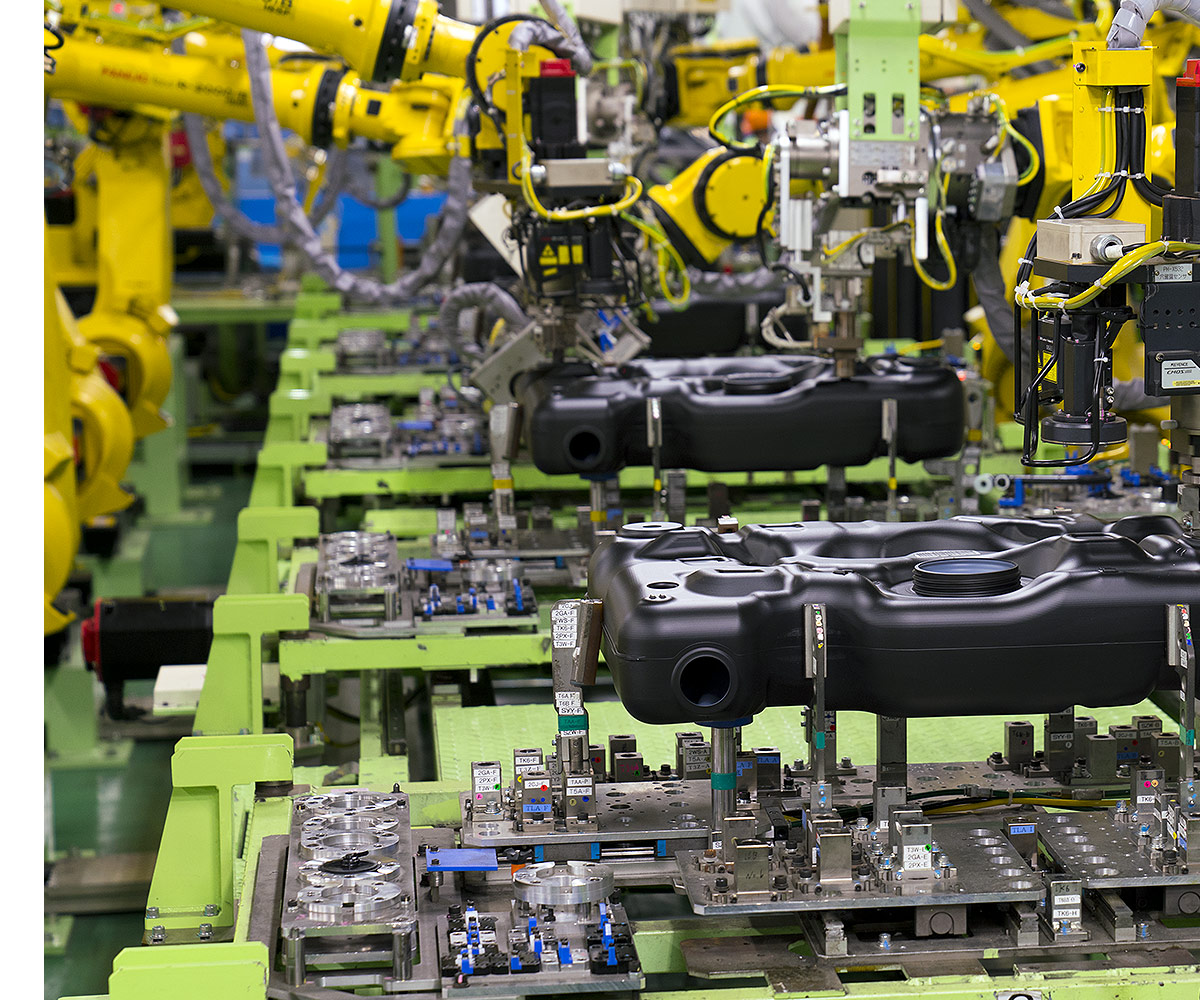

Strict product quality is required in order to comply with crash safety design and environmental regulations. In addition, in order to contribute to creating a larger interior space and reducing the weight of cars, there has recently been an increase in the replacement of steel products with plastic products.

Yachiyo responds to customer needs with a variety of technologies, including compliance with environmental regulations in various regions around the world and support for vehicle electrification.

Product Features

Tank Layer that does Not Release Harmful Chemicals into the Air

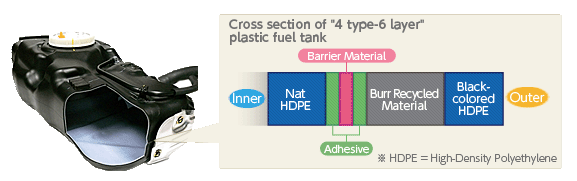

It consists of 6 layers of 4 types of materials, with a layer of EVOH (ethylene vinyl alcohol) in the center.

This EVOH layer prevents hydrocarbons, which are harmful components in gasoline, from permeating through the tank layer and being released into the air.

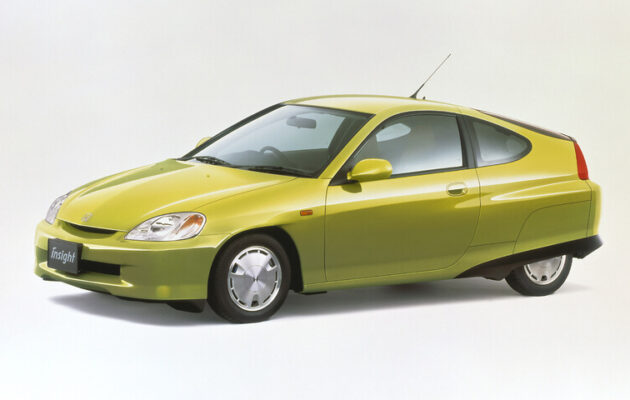

This 4-type, 6-layer structure was first mass-produced by Yachiyo in Japan, and was installed in Honda’s first hybrid car ‘Insight’ in 1999.

In addition, we utilize the plastic burrs generated during tank molding as recycled materials, using a manufacturing method that does not waste materials.

Honda Insight (1999-2006)

Efforts to Realize Weight Reduction

The plastic fuel tank, which is one of its characteristics, has been made even lighter.

By using a plastic material with higher rigidity than before, we are able to make the tank body as thin as possible while maintaining its rigidity, pressure resistance, and impact resistance.

Compliant with Environmental Regulations in Various Regions around the World

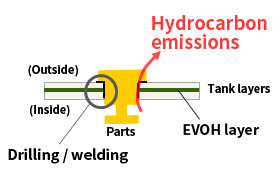

Hydrocarbons emitted by vehicle fuel systems are subject to stricter regulations around the world, just as they are for vehicle exhaust gases.

Yachiyo has cleared this environmental regulation by our own technology.

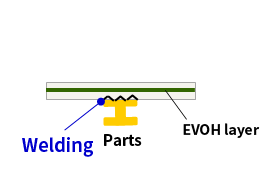

- < Conventional manufacturing method >

Make a hole in the tank - layer and install parts

Drilling a hole divides the EVOH layer and releases hydrocarbons into the air

- < WIB manufacturing method >

Technology for internally welding small parts

(WIB: Welded Inner Baffle)

Weld small parts to the inside of the tank using the holes drilled to attach large parts.

⇒ The holes that divide the EVOH layer are decreased

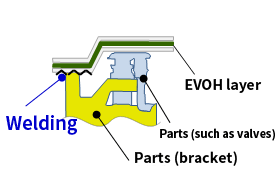

- < BFS manufacturing method >

Technology for internally welding large parts

(BFS: Built-in Fuel System)

In order to weld large parts to the inside of the tank, weld and confine the parts at the same time when forming the tank body.

⇒ The holes that divide the EVOH layer are decreased significantly

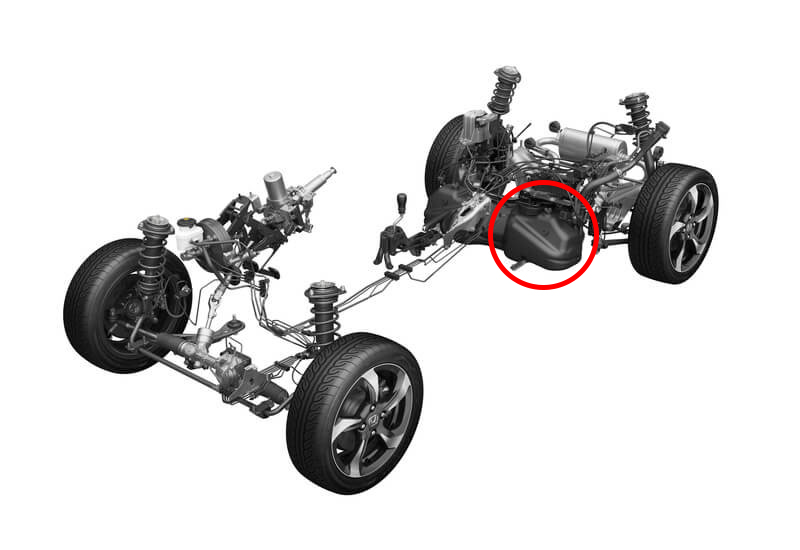

High Degree of Freedom in Shape

spacious interior and improving the car’s weight balance while ensuring the necessary fuel capacity.

It is also one of the elements that make up Honda’s “center tank layout” and “ultra-low-floor platform.

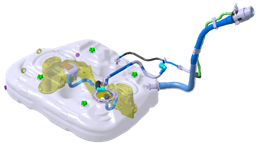

Responding to Vehicle Electrification (high-pressure sealed tank)

In hybrid vehicles, which run on both the engine and electric motor, fuel remains in the tank for a long time. In particular, plug-in hybrid vehicles (PHEVs) require fuel tanks that can withstand pressure changes, as the fuel expands and contracts within the tank over long periods of time.

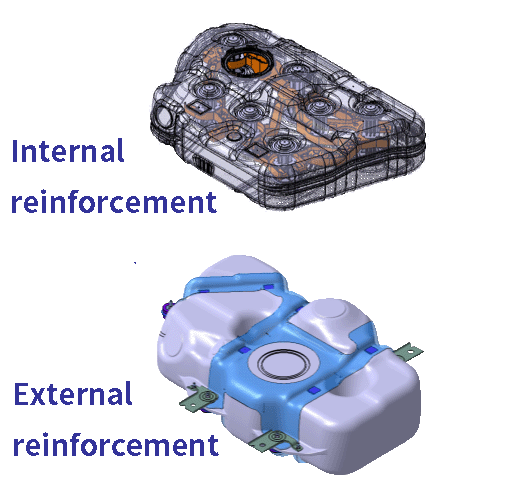

Yachiyo has developed its own technology to withstand this pressure change, and has completed technological development for internal reinforcement tanks, and has adopted external reinforcement tanks for ‘CRIDER’ of Guangqi Honda Automobile Co., Ltd. to respond to vehicle electrification.

Production Locations

| Japan | Suzuka Plant |

|---|

Energy Storage Deployment

Yachiyo is leveraging the technology and know-how it has cultivated with plastic fuel tanks to develop “energy storage” that stores energy other than gasoline and diesel oil, and is conducting research and development on hydrogen storage toward the realization of a hydrogen society.